In the world of design, manufacturing, and engineering, software tools are critical for bringing ideas to life. Among these tools, CAD software—short for Computer-Aided Design—is widely recognized for its role in creating detailed models and technical drawings. However, not all software related to design or manufacturing falls under the CAD category. One such software often questioned is Capstone software. Many ask: is Capstone software considered CAD? This article aims to clarify this question by exploring what Capstone software is, how it is used, and whether it qualifies as CAD.

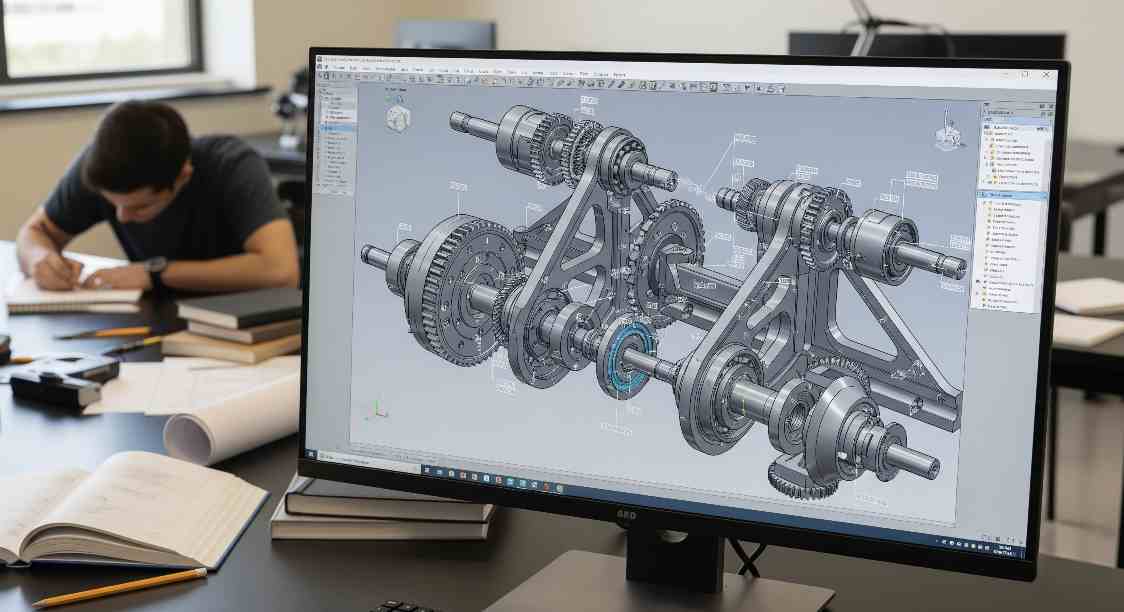

To determine if Capstone software is CAD, it’s important first to understand what CAD software entails. CAD programs are designed to assist engineers, architects, designers, and manufacturers in creating precise drawings and 3D models of physical objects. These tools allow for detailed visualization, modification, and documentation of design elements before any physical production occurs.

Typical features of CAD software include:

- Creation of 2D drawings and 3D models.

- Ability to modify and manipulate designs easily.

- Simulation and analysis capabilities.

- Exporting designs for manufacturing or further processing.

Popular CAD software examples include AutoCAD, SolidWorks, and Fusion 360.

Capstone software is a specialized tool primarily used in CNC (Computer Numerical Control) machining and manufacturing. Its focus lies in converting design files—often created using CAD software—into precise instructions that CNC machines follow to manufacture parts.

Key functions of Capstone software include:

- Toolpath generation: Creating the paths that cutting tools will follow on CNC machines.

- Simulation: Testing the toolpaths virtually to detect errors or collisions.

- Post-processing: Converting toolpaths into machine-specific code (G-code) that CNC machines understand.

- Optimization: Improving machining efficiency by optimizing cutting sequences and parameters.

Unlike CAD software, Capstone does not typically create original designs or models. Instead, it works downstream in the manufacturing workflow, taking existing CAD files and translating them into actionable machine instructions.

Based on the definitions and functions outlined above, Capstone software is not considered CAD software. Instead, it falls into a category known as CAM (Computer-Aided Manufacturing) software.

While CAD focuses on design and modeling, CAM focuses on manufacturing processes. Capstone serves as a bridge between the design phase and the actual machining or production phase by preparing and optimizing the instructions that CNC machines use.

Therefore, Capstone and CAD software are complementary but serve different purposes:

- CAD software: Creates and modifies designs.

- Capstone software (CAM): Translates designs into manufacturing instructions.

Knowing whether Capstone is CAD or not is important for several reasons:

- Selecting the right tool: Designers and engineers need to choose software that matches their stage in the product development cycle. CAD is needed for design, while CAM like Capstone is essential for manufacturing.

- Workflow integration: Effective product development often involves seamless integration between CAD and CAM software. Using Capstone alongside CAD software can streamline manufacturing but requires understanding each tool’s role.

- Training and skills: Professionals need to learn different skill sets for CAD and CAM. Confusing the two could lead to inefficiencies or errors in design or production.

In practical applications, CAD and Capstone software are often used together. A designer might create a detailed 3D model using CAD software, then export that model to Capstone to develop the machining toolpaths. This collaboration ensures that the design intent is accurately translated into physical parts.

Many manufacturers rely on this tandem approach to produce complex components efficiently and accurately.

In summary, Capstone software is not considered CAD. It belongs to the CAM category, focusing on the manufacturing side of product development by converting CAD designs into CNC machine instructions. While CAD software helps create and modify designs, Capstone software optimizes and prepares those designs for machining.

Understanding this distinction is crucial for professionals involved in design and manufacturing to select appropriate tools and streamline their workflows. Both CAD and CAM software like Capstone play vital roles, but they serve different functions in the journey from concept to finished product.